The automatic egg tray production line is composed of pulping system, forming system, drying system, stacking system, vacuum system, high pressure water system and air pressure system.Using waste newspapers, waste carton paper, office paper, scraps and other waste paper as raw materials, through hydraulic disintegration, filtration, water injection and other processes to prepare a certain concentration of slurry, through the molding system on the special metal mold through vacuum adsorption A wet blank is formed, which is then dried on a drying line, and then stacked after being hot-pressed on-line.

| Model | YB-1*3 | YB-1*4 | YB-3*4 | YB-4*4 | YB-4*8 | YB-5*8 | YB-6*8 |

| Capacity (pcs/h) | 1000 | 1500 | 2500 | 3500 | 4500 | 5500 | 7000 |

| Forming Mould Quantity | 3 | 4 | 12 | 16 | 32 | 40 | 48 |

| Total Power (kw) | 40 | 40 | 50 | 60 | 130 | 140 | 186 |

| Electricity Consumption (kw/h) | 28 | 29 | 35 | 42 | 91 | 98 | 130 |

| Worker | 3-5 | 4-6 | 4-6 | 4-6 | 4-6 | 5-7 | 6-8 |

1*3 customer site

1*4 all-in-one machine test machine

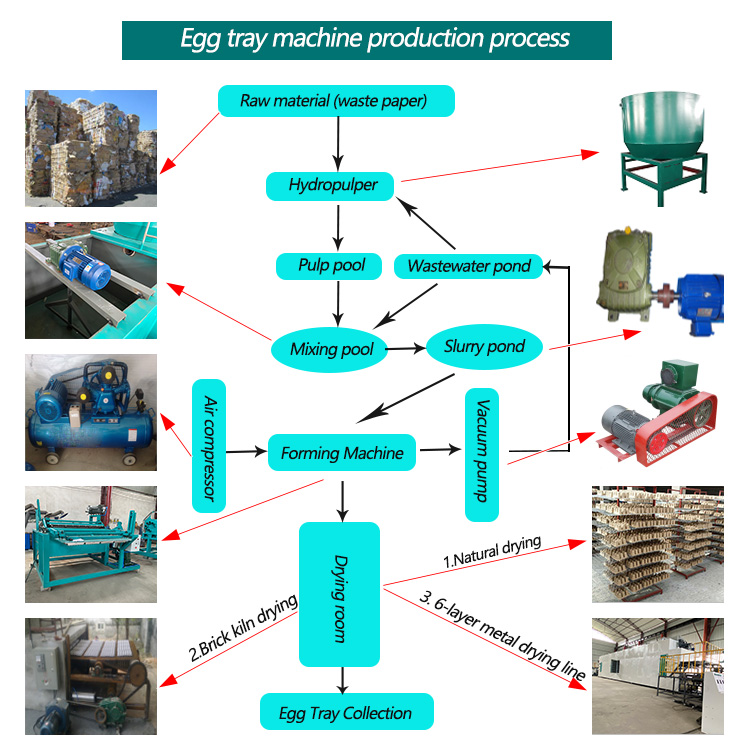

Production process:

1.Pulping system

Put the raw material into the pulper and add an appropriate amount of water for a long time to stir the waste paper into pulp and store it in the storage tank.

2. Forming system

After the mold is adsorbed, the transfer mold is blown out by the positive pressure of the air compressor, and the molded product is blown from the molding die to the rotary mold, and is sent out by the transfer mold.

3. Drying system

(1) Natural drying method: The product is dried directly by weather and natural wind.

(2) Traditional drying: brick tunnel kiln, heat source can choose natural gas, diesel, coal, dry wood

(3) New multi-layer drying line: 6-layer metal drying line can save more than 30% energy

4. Finished product auxiliary packaging

(1) Automatic stacking machine

(2) Baler

(3) Transfer conveyor

1. The host adopts Taiwan gear divider technology to achieve the operating accuracy of the equipment with 0 errors.

2. The main machine base of the egg tray machine adopts thickened 16# channel steel, and the drive shaft is precision machined with 45# round steel.

3. The main engine drive bearings are all made of Harbin, Watt, and Luo bearings.

4. The host positioning slide is welded with 45# steel plate after heat treatment.

5. Slurry pumps, water pumps, vacuum pumps, air compressors, motors, etc. are all made of domestic high-quality brands.

4*8 metal drying test machine

6*8 metal drying site

More Details

Remarks:

★. All equipment templates can be customized in size according to actual customer requirements.

★. All equipment is welded with national standard steel.

★. Important transmission parts can be driven by imported NSK bearings.

★. The main engine drive reducer adopts heavy-duty high-precision reducer.

★. The positioning slide adopts deep processing, anti-wear and fine milling.

★. The whole machine motor is all domestic first-line brands, guaranteed to be 100% copper.

★. Protective measures are adopted for electrical appliances, machinery, pipelines, etc. to extend the service life.

★. Provide customers with detailed equipment layout plans and use drawings for free.

-

1*4 waste Paper Pulp Molding Drying Egg Tray Ma...

-

Young Bamboo paper egg tray making machine auto...

-

Automatic paper pulp egg tray production line /...

-

Waste Paper Recycling Egg Carton Box Egg Tray M...

-

Fully automatic egg tray making machine egg dis...

-

YB-1*3 egg tray making machine 1000pcs/h for bu...