The full name of the facial tissue machine is the boxed facial tissue machine. It is the most common type of boxed facial tissue machinery and equipment. It processes the cut tissue and folds it into facial tissues. After the box is packed, it becomes a pumping boxed facial tissue machine. When used, one piece after another is drawn out of the box, which is convenient and trouble-saving.The boxed facial tissue machine adopts vacuum adsorption and automatic counting and stacking devices, which have the advantages of fast speed and accurate quantity. It is an advanced equipment for the production of boxed facial tissues.

working principle

Facial tissue machine slitting system:

It consists of a saw belt, a pulley, and a working plate. There is a product size adjustment device on the working plate to make the product adjustable.

Folding forming: With the operation of the main motor, the crank rod mechanism of the folding manipulator is produced in conjunction, and the yaw angle can be adjusted by adjusting the position of the crank arm and changing the length of the connecting rod (once the folding forming is fixed, there is no need to adjust it).

Counting stacking: Adjust the budget number of the counting controller. When the number reaches a fixed value, the relay drives the cylinder to produce the displacement of the finished export platen.

The technical principle of boxed pumping facial tissue machine

1. The technology of vacuum adsorption and automatic counting is adopted, so that the speed is fast and the quantity is accurate.

2. The raw materials of the slotted tray paper technology are used, so that the processed paper is folded into facial tissues, which is convenient to be drawn out from the box one by one when used.

Product Usage:

The paper machine folds and cuts the paper, so that the raw material is folded into an "N" type paper towel, which is convenient for people to use

Labor required:

One person is required for a small paper machine, and two people are required for a large paper machine

Venue required:

50-200 square meters (including production area and warehouse area) (paper extraction is strictly controlled, and the highest available dust-free workshop)

Raw materials used:

The small paper machine can use the coil paper (the finished product of the large roll paper is cut by the roll paper slitter), and the large paper machine can directly load the large roll paper

Finished model:

It can produce soft tissue paper and two kinds of boxed tissue paper (only the selected packaging machine is different, the paper extraction machine is the same). Paper drawers can be used in gas stations, KTVs and restaurants to advertise using outer boxes.

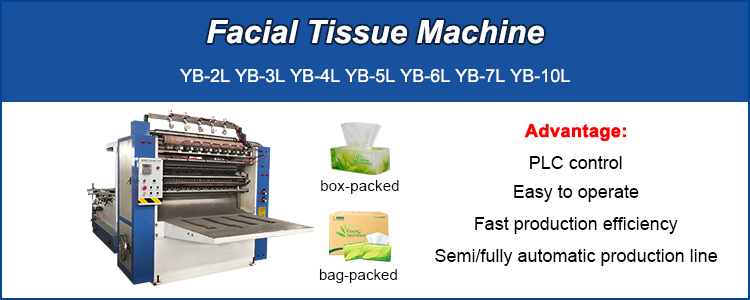

Model parameters:

Voltage: 220V/380V

Power: 11kw 13kw 15.5kw 20.5kw

Weight: 1.8T 2.2T 2.6T 3.0 T 3.5T

Size: 4.9m*1.1m*2.1m 4.9m*1.3m*2.1m 4.9m*1.5m*2.1m 4.9m*1.7m*2.1m 4.9m*1.9m*2.1m

For more products and detailed quotations,Welcome to contact us.

Post time: Mar-28-2023