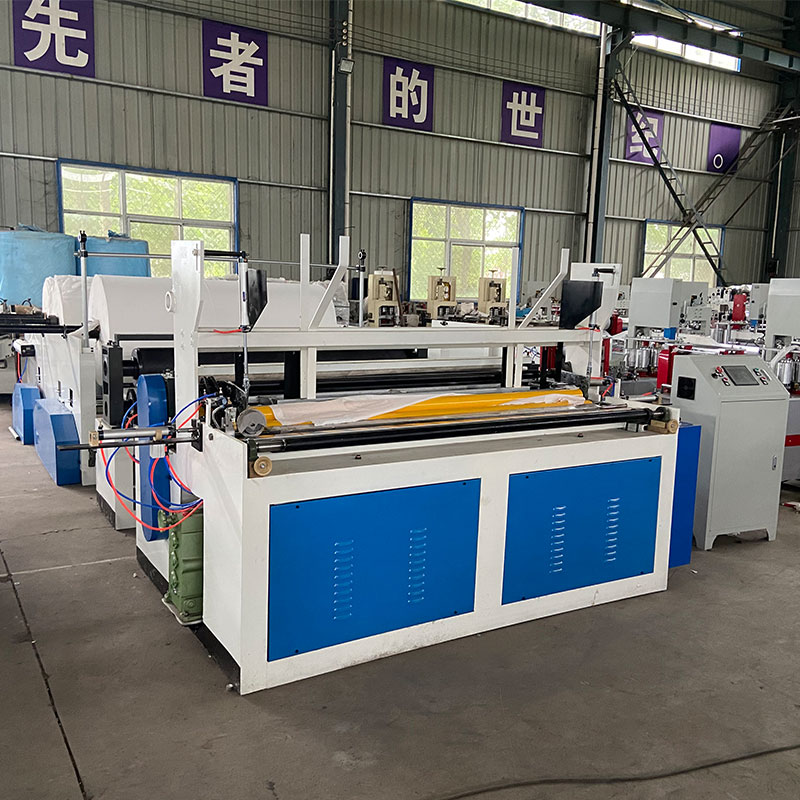

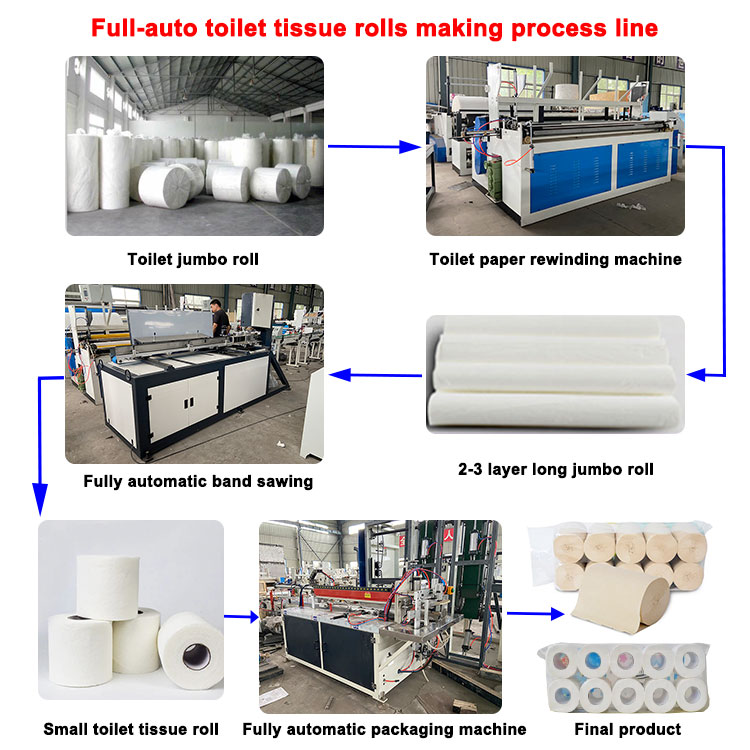

Automatic High Speed Toilet Paper/ Maxi Roll Rewinding Machine is for toilet paper roll/maxi roll processing. Machine have core feeding unit, can do both with and without core. Raw material from jumbo roll after full embossing or edge embossing, then perforation, end cutting and spray the tail glue become a log. Then it can working with cutting machine and packing machine to become the finished products. The machine is controlled by PLC, people operate it through touch screen, the whole process is automatic, easy to operate, lower the man cost. And Our machine can special-made according to clients' requirements.

| Item | Toilet Paper Making Rewinding Machine |

| Model Number | YB-1880 |

| Paper Width | 1880mm |

| Finished Diameter | 50-1880mm adjutable width |

| Base Diameter | 1200mm(Other size are available) |

| Jumbo Roll Core Diameter | Standard 76mm |

| Process Capability | 80~280m/min |

| Back Stand | Standard three layersynchronous transmission |

| Parameter Setting | PLC computer operating system interface |

| Perforation Pitch | 2: 150~300mm 3: 80~220mm |

| Pneumatic System | The 3 horse air compressor,a minimum pressure of 5kg/cm2Pa |

| Power | Stepless variable speed |

| Weight | 2800kg |

| Dimension | 6200*2600*800mm |

1, PLC used in automatic rewinding, automatic delivery of finished products, immediately reset rewinding, automatic trimming, spray glue, sealing synchronization once completed. Instead of the traditional waterline trimming, to achieve a new trimming sticky tail technology, finished products left 10mm-20mm tail, easy to use. To achieve a loss of paper tail, thereby reducing costs.

2, PLC used in the finished product in the rewinding process before the first loose, to solve the finished product for a long time storage, loose core phenomenon.

3, the application of the original paper monitoring system, broken paper automatically shut down. In the high-speed operation of the process, real-time monitoring of the base paper to reduce the loss caused by broken paper to ensure the normal operation of high-speed equipment.

-

Manual band saw paper cutting machine for semi ...

-

Automatic Spiral Paper Core Making Machine Pipe...

-

Semi-automatic Napkin making machine production...

-

YB-1*3 egg tray making machine 1000pcs/h for bu...

-

Full automatic toilet paper single-roll packagi...

-

Young Bamboo paper facial tissue log saw cuttin...