The paper machine is a professional equipment for paper. The slitted paper paper is cut by a spiral knife roll, and the interlocking type is folded into a chain type rectangular towel to draw paper. Product use: The paper machine folds and cuts the paper, so that the raw material is folded into an "N" type paper towel for people to use.

Need labor: Small paper machine requires one person, large paper machine requires two people.

Requires site: 50-200 square meters (including production area, warehouse area) (strict paper control, the highest available dust-free workshop).

Use of raw materials: Small paper machine can use the paper (the large shaft paper is cut through the paper cutting machine). The large paper machine can directly on the large shaft paper.

Finished product type: It can produce soft paper, boxed paper (only the different packaging machines are used, the paper machine is the same), soft paper can be used in family life, carry it, or bag Printed advertisements are used by hotels; boxed paper can be used for advertising at gas stations, KTVs and restaurants.

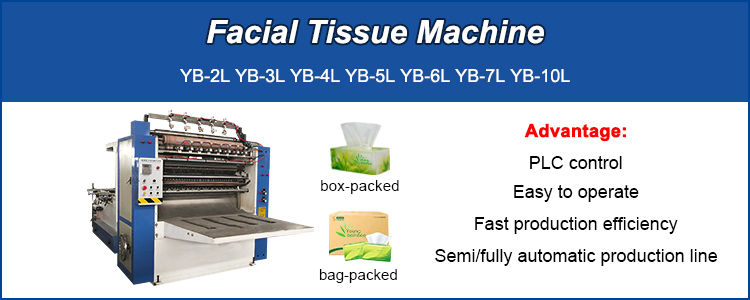

| Machine Model | YB-2L/3L/4L/5L/6L/7L/10L |

| Product Size(mm) | 200*200(Other Size are Available) |

| Raw paper weight(gsm) | 13-16 gsm |

| Paper Core Inner Dia | φ76.2mm(Other Size are Available) |

| Machine Speed | 400-500 pcs/Line/minute |

| Embossing Roller End | Felt Roller,Wool Roller,Rubber Roller,Steel Roller |

| Cutting system | Pneumatic point cut |

| Voltage | AC380V,50HZ |

| Controller | Electromagnetic speed |

| Weight | Depending on the model and configuration to the actual weight |

Slitting system: It consists of a saw belt, a pulley and a working plate. The working plate has a product size adjustment device to make the product adjustable.

Folding and forming: With the main motor running, the folding arm mechanism of the folding manipulator is matched, the yaw angle, the position of the adjustable arm and the length of the connecting rod are adjusted (the folding forming is not necessary after adjustment).

Misalignment Counting and Stacking: Adjust the budget of the counting controller. When the number reaches a fixed value, the relay drives the cylinder to produce the displacement of the finished exit platen.

1. Automatic counting and dividing the entire output;

2. Spiral cutter body shearing, vacuum adsorption folding;

3. Stepless speed regulation unwinding, can adapt to high and low tension of the base paper;

4. Electronically controlled pneumatic, easy to operate;

5. Product width can be adjusted to facilitate customer marketing;

6. Supporting paper surface rolling pattern device, obvious pattern and flexible market demand. (pattern is selected by the guest)

7. Supporting two-color flexographic printing device with bright patterns.

-

YB-4 lane soft towel facial tissue paper making...

-

High speed 5line N folding paper hand towel mac...

-

7L Automatic Facial Tissue Paper Making Machine...

-

6 lines facial tissue paper machine automatic t...

-

YB-3L automatic facial tissue paper machine pro...

-

Factory Price Embossing Box-Drawing Soft Facial...