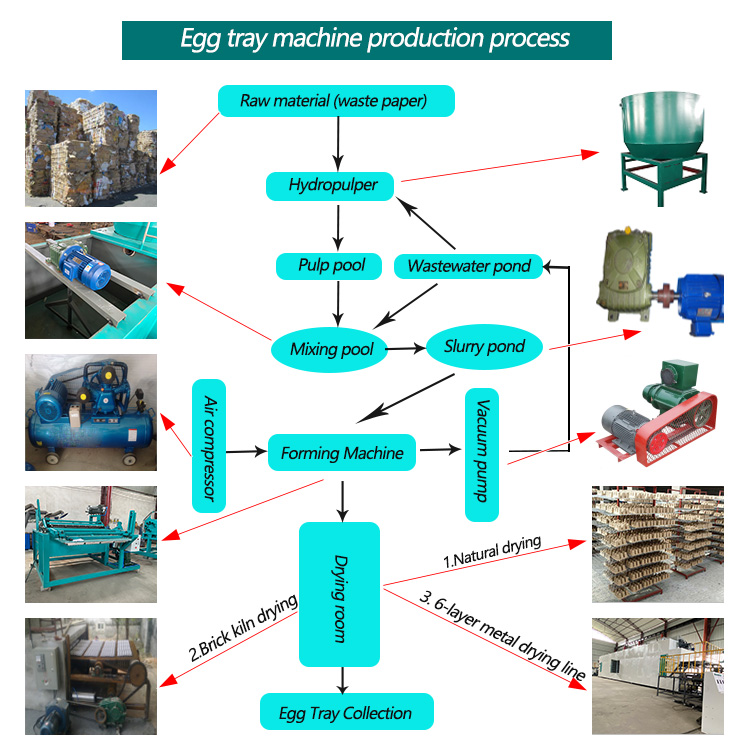

Paper Egg Tray Machine is used to process raw material waste paper into egg tray/carton/box, bottle holder, fruit tray and shoe cover etc. Whole production will be finished by one production line. In this production line, their main engine has three types: reciprocating type, Tumblet Type and rotation typewhich working method is different. Usually rotation type machine capacity is bigger.

About dryer, if you choose reciprocating type production line, because of small capacity, you can dry them naturally also can be dry using our cart-type dryer. On account of bigger capacity tumblet type and rotation type, you can choose mesh-belt dryer to dry tray.

Mould can be customized according to customer's requirements.

The raw materials are mainly from various pulp boards such as reed pulp, straw pulp, slurry, bamboo pulp and wood pulp, and waste paperboard, waste paper box paper, waste white paper, paper mill tail pulp waste, etc. Waste paper, widely sourced and easy to collect. The required operator is 5 people/class: 1 person in the pulping area, 1 person in the molding area, 2 people in the cart, and 1 person in the package.

|

Machine Model

|

1*3

|

1*4

|

3*4

|

4*4

|

4*8

|

5*8

|

5*12

|

6*8

|

|

Yield(p/h)

|

1000

|

1500

|

2500

|

3000

|

4000-4500

|

5000-6000

|

6000-6500

|

7000

|

|

Waste Paper(kg/h)

|

80

|

120

|

160

|

240

|

320

|

400

|

480

|

560

|

|

Water(kg/h)

|

160

|

240

|

320

|

480

|

600

|

750

|

900

|

1050

|

|

Electricity(kw/h)

|

36

|

37

|

58

|

78

|

80

|

85

|

90

|

100

|

|

Workshop Area

|

45

|

80

|

80

|

100

|

100

|

140

|

180

|

250

|

|

Drying Area

|

No need

|

216

|

216

|

216

|

216

|

238

|

260

|

300

|

2.Power means the main parts,not include dryer line

3.All fuel use proportion are calculated by 60%

4.single dryer line length 42-45 meter,double layer 22-25 meter,multi layer can save workshop area

-

Waste Paper Recycling Egg Carton Box Egg Tray M...

-

Fully automatic egg tray making machine egg dis...

-

Automatic waste paper pulp egg tray making mach...

-

Automatic paper pulp egg tray production line /...

-

Egg Tray Pulp Molding Making Machine for Small ...

-

YB-1*3 egg tray making machine 1000pcs/h for bu...